Performance Output

- Units wrapped and sealed at speeds up to 90 ppm

Applications

- fresh, frozen, & prepared foods

- produce

- consumer goods

Style

- extended end seal (crimp)

Film Types

- polyester

- polypropylene

- printed or clear film

- perforated film

Compact, Flexible package sizes, Low maintenance, Easy changeover

AmeriPak’s exceptionally versatile Series 90 wrappers are designed to minimize downtime while decreasing maintenance and increasing productivity.

Product operating parameters may be set within 15 saved files and recalled instantly for fast, accurate product changeover.

An adjustable forming box functions with a variety of products and also allows for fast product size changeover—no tools required.

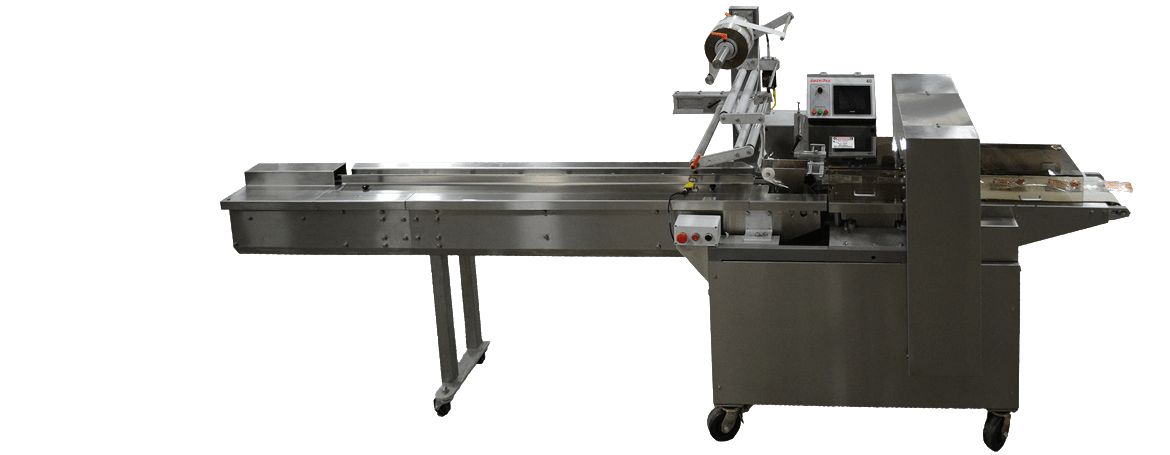

The Series 90 is surprisingly compact, saving valuable floor space while offering 4 1⁄2 feet of unobstructed product feeding space.

A variety of roll stock materials, printed or clear films are suitable on these machines.

H90 Horizontal Flow Wrapper

The H90’s unique EZ-SET end crimper phasing control allows the operator to position the crimper between products during initial setup, then easily fine tune the setting—all while the machine is running. It is powered by a robust 1⁄2 HP AC drive motor.

Technical Specifications

Performance Output

up to 90 ppm,

based on a 6” long bag

Utility Connection

Electric

230V, 3PH, 60Hz

Dimensions

Machine Size (Approx.)

Length: 155”

Width: 36”

Height: 62”

Infeed Conveyor

Length: 92”

Feed Space: 54”

Height above floor: 37”

Product Discharge

Conveyor

24” Standard

48” Optional

Weight

900 lbs base machine

Packaging Specifications

Maximum Package Size

(Not tolerated simultaneously)

Length: 16”

Width: 7”

Height: 2 5⁄8” Standard 3 1⁄2” Optional

Wrapping Material

Max. Roll Diameter: 13”

Max. Roll Width: 20”

Fin Seal Assembly (length seal)

First set – Pulling

Second set – Sealing

End Crimper (cross seal)

1-up x 8” wide Standard

1-up x 10” wide Optional

Standard Features

- Touch screen monitor

- Program up to 15 products

- Left-to-right product flow, facing the control panel

- Powder coated frame

- Stainless steel covers

- Food contact approved conveyor

- Overload clutch on crimpers

Optional Features

- USDA-compliant infeed conveyor

- Relieved upper crimper shaft

- Roller rider conveyor

- Dual parent roll

- Extended infeed sections

- Dual pitch infeed conveyor

- Stainless steel frame & shafts

- Printer / code date interface

- Electric eye film registration

- No product – No bag

- No gap – No seal

Optional Accessories

- Lazy Susan (rotary turn table)

- Adjustable side table

- Spare parts kit